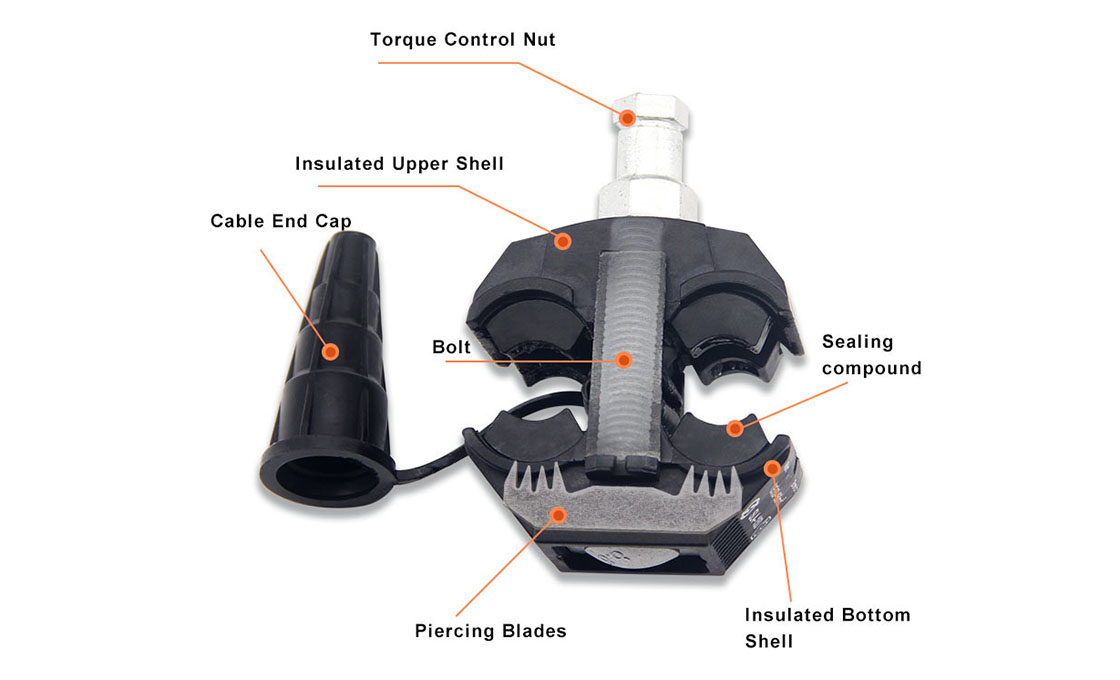

Description: The insulation piercing connectors are applicable for all types of LV-ABC conductors as well as connections in service line system, building electrical system and street lighting system. Insulation piercing connectors can be easily done by tightening the bolts to force the teeth penetrate the insulation of main line and tap line simultaneously. Stripping of insulation is avoided for both lines.

● Main line: Insulated aluminium cable

● Tap line: Insulated aluminium cable or Insulated copper cable

● Body is moulded from tough and weather resistant materials

● Special designed shear head bolt allows efficient installation under controlled shear torque which ensure the contact teeth properly penetrate the conductor without damaging the mechanical strength of the conductor

● Tested for watertightness at the voltage of 6kV for 1min under water

● Safe live-line installation

● Seals and grease are applied to prevent moisture entering the cable and connector which guarantees excellent waterproof and corrosion resistant performance

● End cap is attached to the body. No loose parts could fall to ground during installation

● Standard: EN 50483-4, NFC 33-020, NFC 33-004

General of insulation piercing connector(lPC)

1.1 Piercing connector, simple installation, need not strip the cable coat.

1.2 Moment nut, piercing pressure is constant, keep good electrìc connection and make no damage to lead

1.3 Self-seam frame,wetproof, waterproof,and anti-corrosion, extend the using life of insulated lead and connector

1.4 Adopted special connectìng tablet, apply to joint of Cu(Al) and Cu(Al) or Cu and Al

1.5 Small electric connecting resistance, connecting resistance less than 1.1 tìmes of the resistance of branch conductor wìth the same length

1.6 Special insulated case body, resistance to illuminatìon and environmental aging, the insulation strength can up to 12KV

1. 7 Arc surface design,apply to connection with the same(different) diameter, wide connection scope(0.75mm2-400mm2)

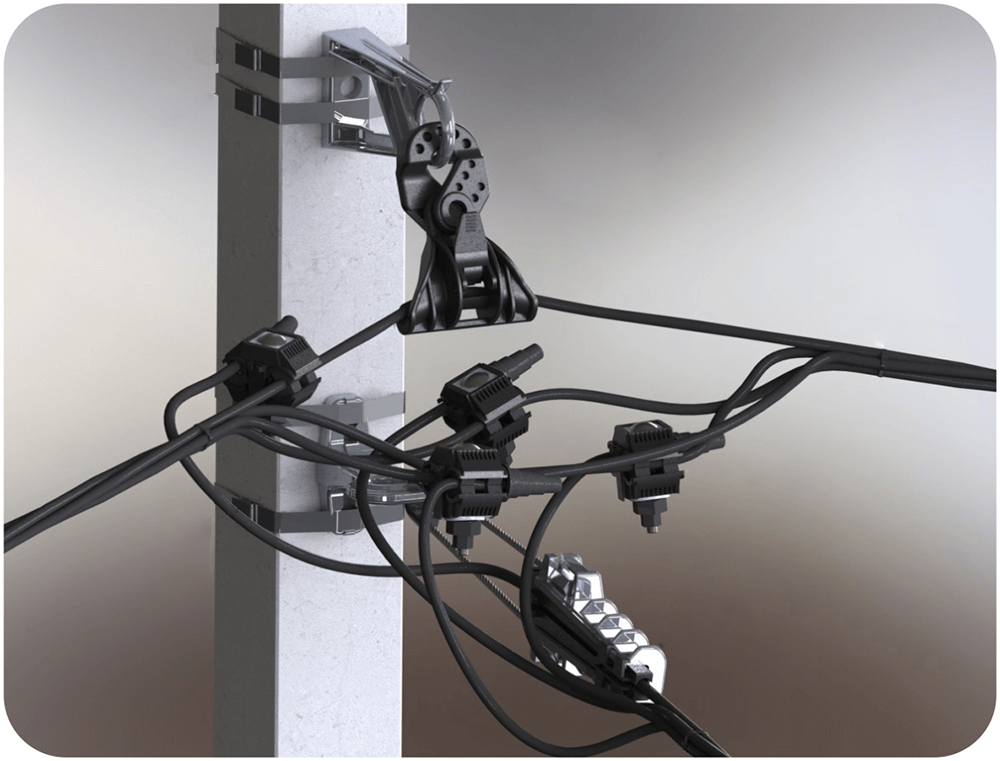

Full range of ABC Insulation Piercing Connectors used to tap off low voltage XLPE insulated Aerial Bundled Cable (ABC).

1).Adjust the connector nut to suitable location.

2).Put the branch wire into the cap sheath fully.

3).Insert the main wire, if there are two lays of insulated lay in the main cable, should strip a certain length of the first insulated lay from inserted end.

4).Turn the nut by hand, and fix the connector in suitable location.

5).Screw the nut with the sleeve spanner.

6).Screw the nut continually until the top part is cracked and dropped down.

Technical specification

|

Dimensions |

|

|

Main Cable Line: |

50-150mm² |

|

Branch Cable Line: |

50-150mm² |

|

Norminal Current: |

316A |

|

Piercing Depth: |

1.5-2.5mm |

|

Features |

|

|

Bolt: |

M8*70 |

|

Mechnical |

|

|

Tightening Torque: |

20Nm |

0086-13968775537(24x7)

Well-trained & experienced staff are to answer all your inquiries.

We are the manufacturer with a brilliant team work team work.

we provide small products to check quality for you, just you pay the express fees